Insulated Underground Pipe

**Please contact us directly to order.

The Value of Underground Pipe

It seems like there are many different manufactures of insulated underground pipe. Choosing the right underground tubing can make a big difference in how effective your outdoor boiler, furnace or stove operates. Effectively choosing and installing quality insulated underground tubing can ensure that your boiler/furnace/stove is operating at peak performance which reduces fuel consumption and improves air quality.

Key Factors

When choosing a type of insulated underground pipe it is important to consider several key points; adequate insulation, climate, length and R values of pipe. Higher R values mean lower heat loss from point A to point B. Lower heat loss will ensure the maximum Btu heat transfer possible and maximum BTU heat output. Milder climates may not require as high R values as colder climates.

R values are determined from the type of insulation being used. Pre-Insulated underground pipe can be manufactured with foam or wrapped with foil blanket like materials. Foil wrapped pipe are considered to be competitively priced and pipe made with foam are designed to respond to intensive environments and climates.

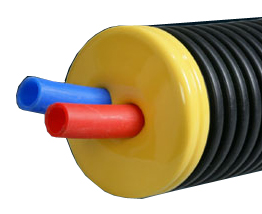

Pre-insulated underground pipe can be manufactured to individual installation needs. Common installs will require one return line and one supply line. For installations that require extra lines this can be easily ordered to meet your requirements.

There are three types of tubing to choose from, barrier, non-barrier and PEX-AL-PEX. When using PEX tubing in an environment such as outdoor boiler applications, expansion is expected because of high temperatures in boiler water. Manufactures will often recommend using PEX-AL-PEX tubing which has less expansion capacity then barrier and non-barier PEX. PEX-AL-PEX lines will maintain their shape and will not cause extra pressure on fittings and pumps due to expansion. PEX-AL-PEX tubing also reflexes true inside diameter (ID) dimensions, barrier and non-barrier PEX will reflex outside diameter (OD). For example, 1” PEX-AL-PEX will measure 1” ID while 1” PEX will measure slightly less than 7/8 inches. Smaller inside diameter dimensions will restrict flow of water which can lead to reduce transferring of BTU’s to point A to point B. Standard PEX tubing comes in two forms, barrier or non barrier. Barrier PEX is similar to PEX-AL-PEX only because it contains an oxygen barrier which will assures that no oxygen will enter the heating system. Oxygen barrier PEX helps prevent cast iron components from rusting over time. However often times non-barrier pex is chosen because of pricing.

Choosing the correct type of insulated underground tubing maximized efficiency of any system by keeping heat loss to a minimum. High efficiency will achieve the maximum delivery of heat from wood and reduces wood consumption and leads to more saving.

Installation

Insulated underground piping should be continuous with no joints, couplings or unions between the building being heating and the boiler. Insulated tubing needs to be free of damages or punctures that will allow ground water or soil to come in contact with the inside insulation and piping. Allowing such contact will cause pipe to become susceptible to water penetration which will lead to major heat loss and ruin any advantage of an outdoor wood furnace. Proper sealing of each end of pipe is also required to ensure complete water tight installation.

Proper burring of pipe is crucial to achieve the best possible heat transfer from point A to Point B. It is recommended whenever possible to bury pre-insulated pipe at least 24“ deep.

ValuFlex

Specifications

- 5″ Corrugated Tubing Diameter

- Polyolefin Tubular Insulation

- Operating Temperatures 300 to 200 Deg F

- Water Perm 0

- Insulation Structure – Closed Cell

- Insulation Density – 1.5 lb

- Absorption 0

- Mold Growth 0

- Lineal Shrinkage – Less then 4%

- R-Value – 8.5

Does not support mold or fungus growth

Coil Sizes available in 100′ and 300′

Outer yellow sealing cap included

| Description | Price (FT) |

|---|---|

| 3/4″ Dual Non-Barrier | $8.77 |

| 3/4″ Dual Oxygen Barrier | $8.83 |

| 3/4″ Dual PEX-Al-PEX | $9.97 |

| 1″ Dual Non-Barrier | $9.13 |

| 1″ Dual Oxygen Barrier | $9.91 |

| 1″ Dual PEX-Al-PEX | 12.49 |

| 1-1/4″ Dual Non-Barrier | $12.31 |

Flexsul-Seal

The characteristics that make rigid Insul-Seal a superior insulator for hot water lines has finally been translated into a flexible version retaining the positive benefits of the original product.

Flexsul-Seal is an elastomeric thermal insulation used to retard heat loss in hot water plumbing and dual hot waterline systems. The Flexsul-Seal system is designed to trap dead air, within an expanded closed cell structure, thus increasing its total R-Value and reducing Heat loss in cold underground burial. Thermal performance is achieved by sealing the 2-5/8″ centered air space, in effect reducing the flow of air and increasing the total R-Value of 6 by and additional factor of 5-9.

PEX tubing carrying hot water needs room to expand and contract. Without needed space to expand, PEX tubing call cull and add unneeded stress at its connections. With the Flexsul-Seal system PEX waterlines have sufficient room to expand and contract with no stress added to connections ends.

For your Outdoor furnace Installation it only make sense to use a quality product. Outdoor wood Boilers can only operate at peak performance when used with a quality insulated piping system. A poor quality insulated system will require substantially more wood and also reduce the amount of heat delivered to heat your home. Flexsul-Seal carries along the tradition of high quality and high standards already established by its manufacturer, Insul-Seal Insulated PVC.

Flexsul-Seal Advantages

- Lightweight – Easy Handling

- High Flexibility

- 5″ I.D. – Increased Insulation Protection

- 50% more insulation area then 4″

- Thermal Dead Air Pocket resulting in increased R-Value

- Decrease Labor Costs

- Joint-Free Installation

- Lighter Weight = Lower Transportation Costs

- Each Coil includes:

- 1 – 5″ Coupling

- 1 – Roll Tape

- 4 – Insulated end caps

Flexul-Seal Specs

- Exterior skin consists of 50 mil Polyethylene Corrugated Tubing

- Exterior skin complies with ASTM F405-97 for H.D. Tubing

- All PEX Tubing Meets Applicable Standards

Thermal Insulation Properties

- Operating Range: -297ºF to 220ºF

- 90% Closed Cell

- .02% Water Absorption by volume

- .10% Water Vapor Permeability

- Passes flame Spread of 25 as tested by ASTM E 84

- Meets requirements of ASTM C 411 for hot surface performance of High Temperature Thermal Insulation

- R-Value = 6 per Inch

- Non-Porous, Non Fibrous Insulation resists mold growth

- 3lb/ft – 6lb/ft Density

| Description | Price (FT) |

|---|---|

| 3/4″ Dual Non-Barrier | $11.64 |

| 3/4″ Dual Oxygen Barrier | $12.01 |

| 3/4″ Dual PEX-AL-PEX | $12.37 |

| 1″ Dual Non-Barrier | $12.19 |

| 1″ Dual Oxygen Barrier | $12.73 |

| 1″ Dual PEX-AL-PEX | $13.87 |

| 1-1/4″ Dual Non-Barrier | $15.37 |

| 1-1/4″ Dual Oxygen Barrier | $24.67 |